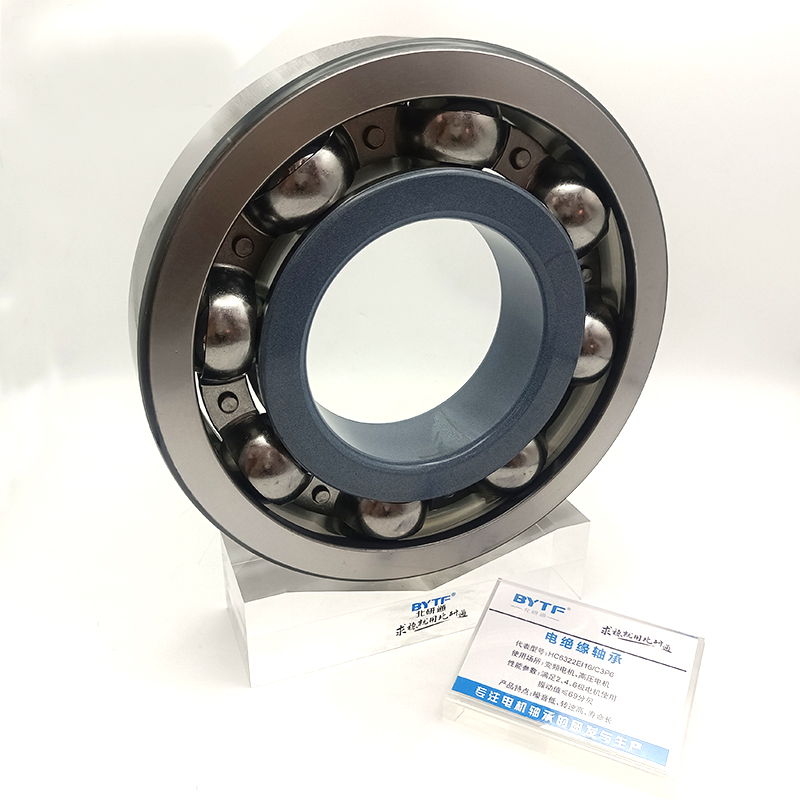

Electric insulated bearings

One or more insulation materials such as ceramics, plastics, rubber, etc. are used on the surface or inside of the bearing to prevent current from passing through the bearing, prevent electrical corrosion and electrical faults of the bearing. The insulation layer is usually formed on the surface or inside of the bearing by special spraying, coating or filling process, and needs to have sufficient insulation strength, abrasion resistance, chemical stability and anti-aging performance.

application area

In the power industry, it is widely used in equipment such as generators and electric motors to avoid bearing damage caused by current, improve the operational reliability and service life of equipment, such as wind turbines, hydro generators, thermal power generators, etc.

Railway transportation: used for traction motors, wheel bearings and other parts of railway locomotives to prevent erosion of bearings by current and ensure the safe operation of railway vehicles.

Industrial production: In high-power variable frequency motors of industrial equipment such as cranes, textile machines, printing machines, ironmaking equipment, steelmaking equipment, steel rolling equipment, as well as high-power high-voltage motors of mining machines, coal preparation machines, coal washing machines, crushers and other equipment, electrically insulated bearings are required to protect the equipment and reduce the occurrence of failures.

In other fields, such as high-power explosion-proof motors for compressors, pumps, and other equipment, as well as equipment that needs to operate in special environments such as high temperature, high pressure, and strong corrosion, electrically insulated bearings can also play an important role in ensuring the normal operation of the equipment.

Explore our products

Rubber sealed deep groove ball bearing

Rubber sealed deep groove ball bearing

Open deep groove ball bearing

Open deep groove ball bearing