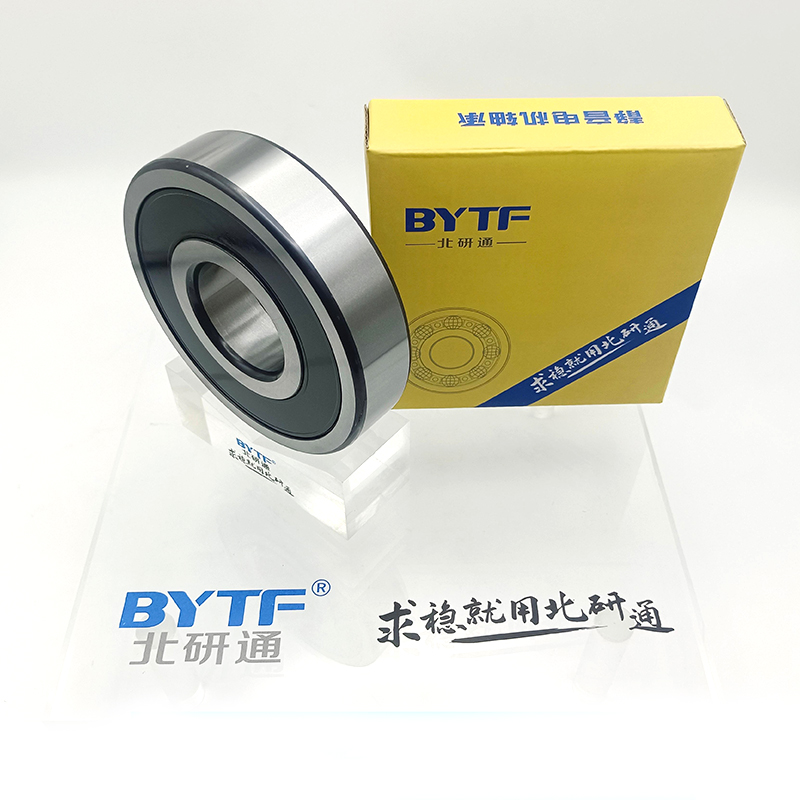

Rubber sealed deep groove ball bearings

Sealing method: Unlike ordinary deep groove ball bearings, rubber sealed deep groove ball bearings use rubber sealing rings for sealing. This type of sealing ring is usually made of materials such as nitrile rubber (NBR) or fluororubber (FKM), which have good elasticity, wear resistance, and oil resistance. The sealing ring is installed on both sides of the bearing, tightly fitting between the inner and outer rings of the bearing, forming a sealed space that effectively prevents external dust, moisture, impurities, etc. from entering the interior of the bearing, and also prevents grease leakage inside the bearing.

Rolling elements and grooves: Maintaining the basic structure of deep groove ball bearings, it consists of an inner ring, an outer ring, rolling elements (steel balls), and a cage. There are smooth circular raceways on both the inner and outer rings, and the rolling elements roll in the raceways, which can withstand radial loads and certain axial loads. The contact area between the rolling elements and the groove of deep groove ball bearings is small, and the friction coefficient is low, therefore it has good rotational flexibility and low operating noise.

Performance advantages

Good sealing performance: The rubber sealing structure can provide reliable sealing effect. Compared with other sealing forms such as dust cover sealing, rubber sealing rings can better block external pollutants and are suitable for harsh working environments such as dusty, humid or oily places.

Good lubrication retention: effectively preventing grease leakage, enabling bearings to maintain good lubrication for a long time, reducing the frequency of grease replenishment, and lowering maintenance costs. Meanwhile, good lubrication also helps to improve the service life and operational efficiency of bearings.

Low friction and high-speed performance: The structural characteristics of deep groove ball bearings themselves give them low friction properties, while the rubber sealing structure ensures sealing performance while having a small impact on the rotational resistance of the bearing. Therefore, rubber sealed deep groove ball bearings can operate stably at high speeds and are suitable for equipment that requires high-speed rotation.

High reliability: Due to its ability to effectively protect the internal components of bearings from external factors, rubber sealed deep groove ball bearings have high operational reliability and can maintain stable performance under various complex working conditions, reducing the incidence of bearing failures caused by poor sealing.

application area

Industrial machinery: widely used in various industrial equipment, such as motors, reducers, fans, pumps, etc. These devices usually operate in different working environments, and rubber sealed deep groove ball bearings can provide reliable support and sealing to ensure the normal operation of the equipment.

Household appliances: There are also a large number of applications in the field of household appliances, such as air conditioning, washing machines, refrigerators, etc. In these devices, bearings need to operate in relatively small spaces and meet the requirements of low noise and long life. The characteristics of rubber sealed deep groove ball bearings can well meet these needs.

Automotive industry: used for engine, transmission, wheel hub and other parts of automobiles. During the operation of automobiles, bearings need to withstand various complex loads and harsh environmental conditions. The sealing performance and reliability of rubber sealed deep groove ball bearings can ensure their stable operation in automobiles, improve the overall performance and safety of automobiles.

Office equipment such as printers and copiers also use rubber sealed deep groove ball bearings. These devices have high requirements for the accuracy, noise, and service life of bearings. Rubber sealed deep groove ball bearings can meet their high-speed and high-precision rotation needs, while ensuring good sealing performance to prevent dust and other impurities from entering the equipment and affecting operation.

Explore our products

Rubber sealed deep groove ball bearing

Rubber sealed deep groove ball bearing

Open deep groove ball bearing

Open deep groove ball bearing