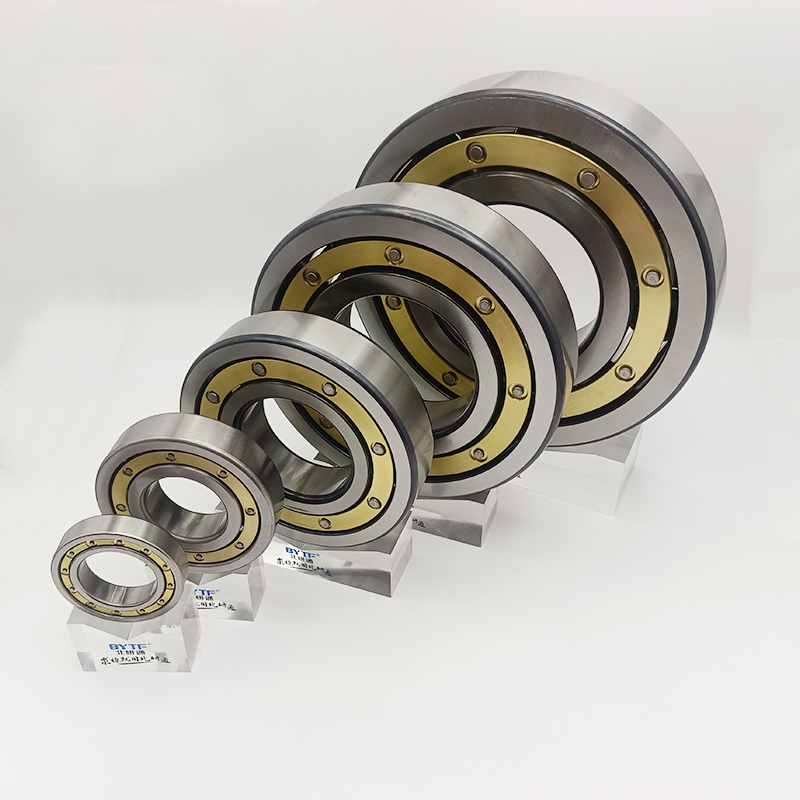

Copper coated deep groove ball bearings

Copper bonded deep groove ball bearing is a type of deep groove ball bearing, where "copper bonded" refers to the use of copper alloy cage for the bearing. Here are some of its features and applications:

characteristic

Advantages of retaining frame: Compared with common steel plate stamping retaining frames, copper alloy car made retaining frames have higher strength and wear resistance. Under high-speed rotation or heavy loads, it can better maintain the position and motion trajectory of rolling elements, reduce collisions and friction between rolling elements, and thus improve the stability and reliability of bearings. For example, in some large motors or high-speed rotating equipment, copper insulated deep groove ball bearings can withstand higher speeds and loads, ensuring stable operation of the equipment.

Good lubrication performance: Copper alloy materials have good thermal conductivity and oil storage properties, which can better dissipate the heat generated during the operation of bearings, store and transfer lubricating oil, maintain good lubrication between rolling elements and raceways, reduce friction coefficient, reduce wear and heat generation, and extend the service life of bearings.

Strong corrosion resistance: Copper alloy has a certain degree of corrosion resistance. In some harsh working environments, such as humid and corrosive gas environments, it can resist the erosion of external media and maintain the performance and accuracy of bearings.

application area

High speed rotating equipment: such as aircraft engines, gas turbines, etc. These devices have extremely high requirements for the speed and reliability of bearings. Copper insulated deep groove ball bearings can maintain stable performance under high-speed rotation, withstand huge centrifugal forces and loads, and ensure the safe operation of the equipment.

Large industrial machinery: such as large motors, reducers, fans, etc. These devices usually need to withstand large radial and axial loads. Copper insulated deep groove ball bearings, with their high-strength cage and good load-bearing capacity, can provide reliable support for these devices, ensuring their normal operation and reducing the frequency of maintenance and bearing replacement.

Precision instruments and equipment: such as machine tools, measuring instruments, etc. In these devices, bearings are required to have high precision, low noise, and low vibration performance. The copper alloy cage of copper bonded deep groove ball bearings can accurately guide the movement of rolling elements, reduce vibration and noise, and improve the machining and measurement accuracy of equipment.

Explore our products

Rubber sealed deep groove ball bearing

Rubber sealed deep groove ball bearing

Open deep groove ball bearing

Open deep groove ball bearing